Services

Services

Promoting Efficient Resource Use for a Sustainable Future

At Tokyo Metal Resource, we are committed to creating an environmentally conscious and sustainable society through our rare metal recycling business. By efficiently reusing and recovering precious metals from industrial waste and other sources, we promote effective resource utilization and contribute to waste reduction.

Leveraging our extensive expertise, knowledge, and technology accumulated over many years, we achieve the recovery of high-purity, high-quality rare metals. This enables us to provide a stable supply of resources to manufacturing and industries both domestically and internationally, supporting the realization of a circular economy.

To minimize environmental impact, we maintain strict standards for the treatment of emissions and wastewater, ensuring clean and responsible processes. Alongside advancing sustainable material development, we strive to maximize the value of recycling and walk hand-in-hand with valuable circular solutions for reusable resources.

Our efforts go beyond resource recovery, creating meaningful value that also supports local economies and employment opportunities.

Rare Metals

Rare metals are critical resources used in electronics, batteries, automobiles, and wind power generators. These metals are extremely scarce in nature and Japan heavily relies on imports. Recycling these resources is both environmentally and economically beneficial.

Products

At Tokyo Metal Resources, we introduce the wide range of resources and materials we handle.

We strive to meet the

diverse needs of our customers by dealing with various materials and resources.

Facilities

Overview

Tokyo Metal Resources is highly regarded for producing high-precision, high-quality products using state-of-the-art

machinery.

Here, we present an overview of our factory and equipment.

-

Portable Component Analyzer

RIGAKU

NITON XL2-980 -

X-ray Fluorescence (XRF) Elemental Analyzer

SII Nanotechnology

SEA1200VX -

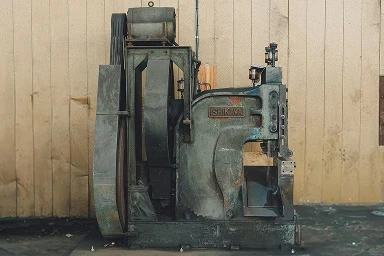

Band Saw

-

Shearing Machine

Process Flow

-

01.

Receiving

・Shape・Physical inspection

・Weighing

・Radiation inspection

-

02.

Analysis

・Component analysis

・Oil and moisture content inspection

・Grade confirmation

・Settlement report

-

03.

Processing & Sorting

・Sorting

・Various processing operations

・Surface cleaning

-

04.

Packaging

・Packing

・Quality preservation management

-

05.

Shipping

・Lot management

・Pre-shipment quality inspection

・Shipping documents